Meet us from 16 to 18 January in the halls of the Nuremberg Exhibition Centre at the

EUROGUSS 2024

Foseco showcases new technologies for die casting at EUROGUSS

The global die casting industry will assemble in Nuremberg, Germany, in January for EUROGUSS 2024 – the leading international trade show for HPDC sector. Taking place in the halls of Messe Nuremberg on 16-18 January, the show and associated technical forum promise the ideal chance to experience the latest trends and innovations in die casting technology and solutions.

In Hall 7A, the Foseco stand will feature many of our recent innovations for non-ferrous foundries and the HPDC section, including:

• Melt treatment

• Crucibles

• Innovative sand core binder solution for HPDC

Visit our global team of experts at Stand No. 7A/134 to discover how we can help solve the most pressing challenges facing the die casting industry today.

Melt treatment

In recent years, we have added a number of features and technologies to our FDU and MTS automated aluminium melt treatment technologies. These advances provide foundries the opportunity to gain new perspective on and control of their treatment process.

Our SMARTT degassing software offers various programs for rotary degassing; the operator must simply define a target melt quality. Based on ambient conditions, melt temperature, rotor design, and alloy composition, the software then calculates the best treatment practice to achieve that goal. Optimisation modes are also available to reduce inert gas consumption, minimise degasser wear, or provide fastest degassing and treatment speed. Treatment parameters are automatically relayed to the FDU MTS equipment, while a customised report system records all parameters.

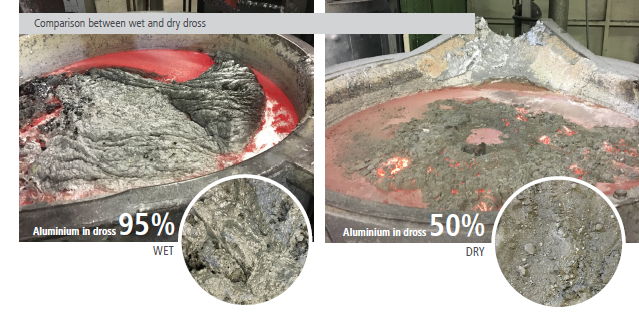

Granulated fluxes can be added through the automated MTS and provide many advantages, such as improved melt fluidity during casting, reduced inclusions, and improved mechanical properties. Our new range of granulated fluxes includes COVERAL, SIMODAL, and NUCLEANT fluxes, which cover the principal foundry operations of cleaning, drossing, modification, and grain refinement. They have been specially formulated for use in conjunction with FDU and MTS to keep smoke and fume to a minimum.

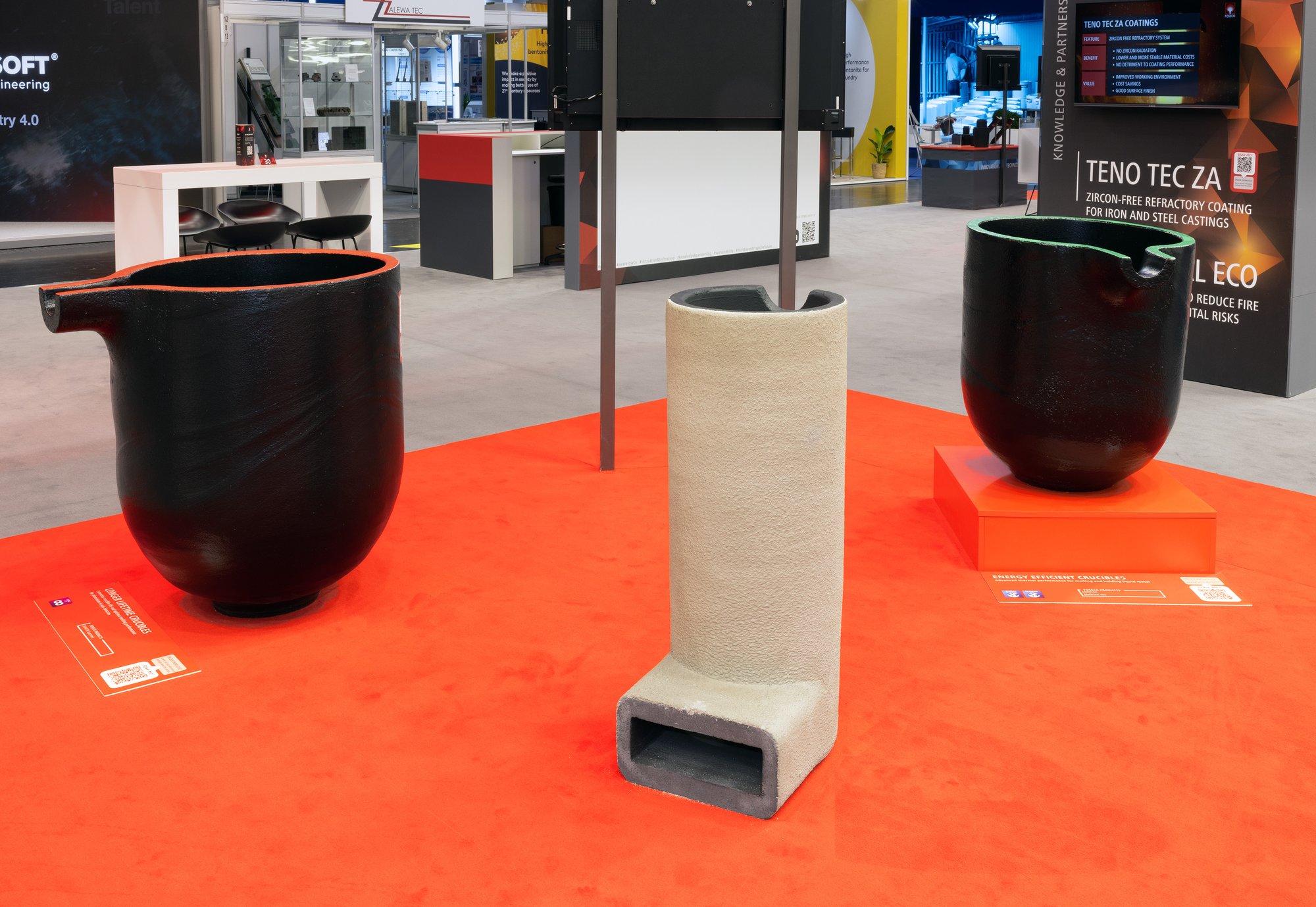

Crucibles

We continuously improve our crucible technology to provide solutions that reduce energy consumption, increase output, and improve production efficiency. Recent innovations on display at EUROGUSS 2024 will include:

- ENERTEK ISO crucibles, which utilise a highly-insulating, proprietary Vesuvius coating to significantly reduce heat loss and decrease energy use in induction melting or continuous casting applications.

- DURATEK crucibles, designed to provide extended life, especially in highly-corrosive conditions. The latest DURATEK Supermelt crucibles possess superior fracture toughness, high temperature strength, and oxidation resistance to ensure long life in aggressive aluminium melting operations.

Innovative sand core binder solution for HPDC

A key limitation of the high pressure die casting process (HPDC) is the inability to produce complex, hollow castings, at high volume, and in a cost-effective and sustainable way. This is due to the difficulty in producing suitable cores. Standard sand cores cannot be used, as they are difficult to remove after casting and do not provide adequate surface finish. Salt cores are more suitable, but are expensive to produce and present other operational limitations.

In response to this challenge, we have developed the WASCO water-soluble binder and coating, which we will showcase at EUROGUSS 2024. This innovative binder system demonstrates high bending strength and has been used successfully in both liquid and semi-solid HPDC processes, even in severe conditions. With the use of an appropriate coating, WASCO based sand cores can exceed 1000N/cm² and are thermally resistant up to 750°C. Post-casting removal is achieved simply by flushing with water, preventing any risk of damage or crack initiation.

Our product range for high pressure die casting

As castings become more complex and some wall sections become heavier, so the advantage of the very rapid cooling rate is reduced and casting defects more commonly seen in gravity die casting and sand casting are now being experienced in high pressure die castings. The current trend to heat treat and weld components places higher emphasis on the internal quality requirements and now increasing levels of inspection and measurement are applied to segregate defective parts. A key enabler to meet these new quality demands is to begin with high quality melt cleanliness. Foseco offers a full range of products that enable HPDC foundries to exceed these increasing demands.

White paper: Challenges for high pressure die casting foundries

What is it about?

The high-pressure die casting (HPDC) market is evolving as auto makers increase both the amount and complexity of aluminium parts involved vehicle production. The change brings new opportunities for HPDC foundries – but also new challenges. Foundry consumable suppliers such as Foseco have a key role in helping their customers overcome these issues and take advantage of the next stage in HPDC evolution. In this white paper, we discuss:

• Current trends in HPDC including lightweighting and megacasting

• The challenges posed by these trends

• How we are supporting foundries take the next steps in HPDC